Wencon Case Stories

Explore how Wencon’s epoxy solutions have been successfully applied across various maritime scenarios. See how our solutions save costs, reduce downtime, and enhance the longevity of ship components.

Find inspiration for maintaining and protecting your vessels more effectively.

Explore a selection of case stories

Vessel Window Repair

Corroded vessel windows were restored using Wencon Coating, ensuring long-term corrosion protection and minimal material waste.

Rebuilding of Stern Boss Flange

Due to bimetallic corrosion the Stern tube Boss Seal Surface has been damaged and required by Class to be recovered.

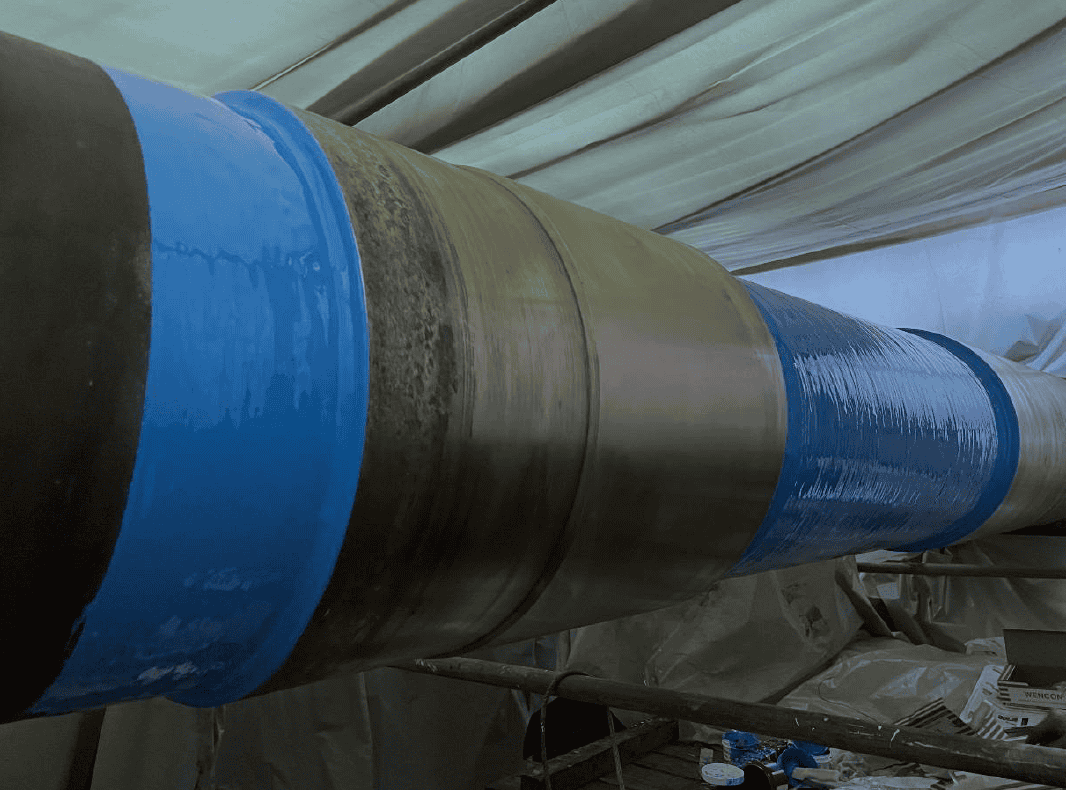

Thruster Gear Housing

With Wencon Standard Coating a thruster gear housing was rebuilt, repaired and protected against corrosion.

Repair of Ballast Pipe System

With the use of UW Coating and reinforcement tape, leakages on a ballast pipe system was repaired.

Exhaust Bellow Repair

A crack in the exhaust bellow appeared and caused visble smoke gas and soot. It was repaired with Exhaust Repair Compound.

Scrubber Outlet Protection

With Wencon Hi-Temp the scrubber outlet was made resistant to scrubber washing and harsh environment.

Coating of Seawater Filter

With Wencon metal free epoxy we avoided bi-metallic corrosion and extended the service life of important equipment on board of a vessel.

Hull Corrosion Protection

Wencon UW Coating proved invaluable for underwater repairs, allowing easy inspection and demonstrating durability six months after.

Scrubber Unit Corrosion

Gasket causing corrosion to spread into scrubber unit. The repair wa completed on both scrubber unit in 13 hours

Repair of Heat Exchange Cover

Due to bi-metallic corrosion, leaking cover

of the heat exchanger, is a common and well

known problem.

Rebuilding of Cylinder Rams

The hydraulic ram was successfully repaired using Wencon Hi Temp. The areas were carefully masked to prevent material waste.

Suction well in Cargo Tank

During drydocking it was decided to protect suction wells in cargo tank against future wear and tear.

Repair of Split Case Pump

A pump inspection conducted after only two years of service uncovered severe corrosion attacks.

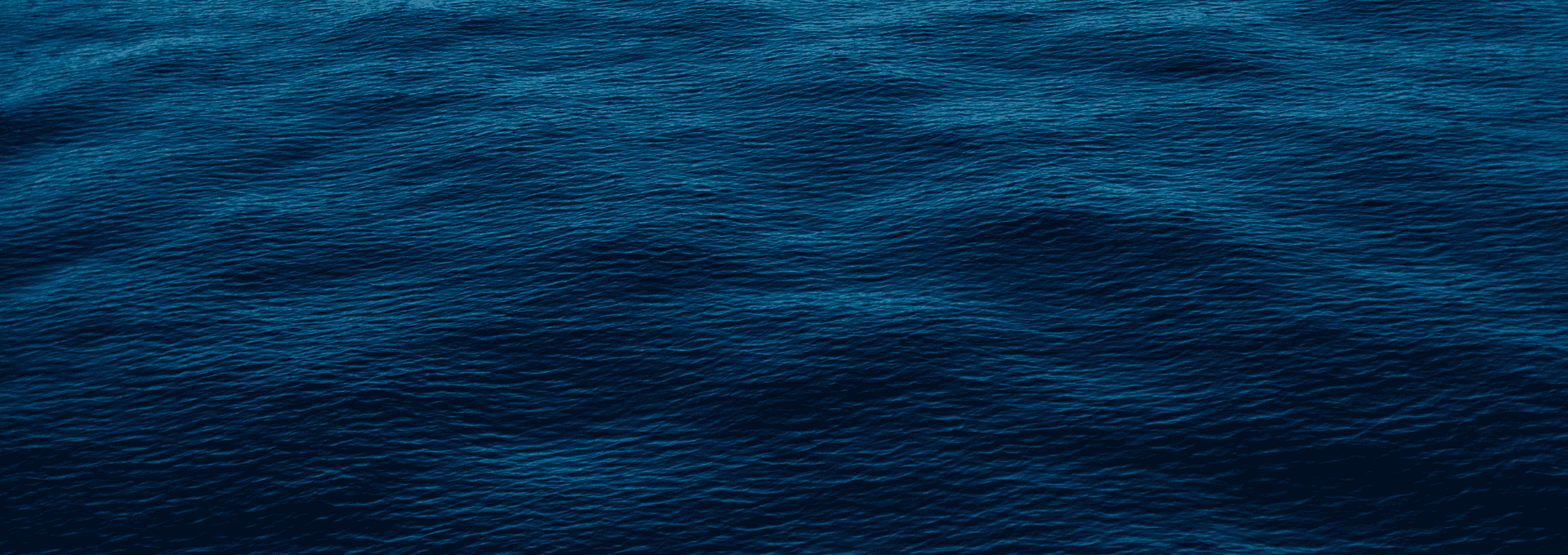

Repair of Rudder Semi Blades

Rudder semi blades was damaged due to cavitation, but rebuilt and protected with Wencon UW Coating and cream.

Cavitated Propeller Blades

8 pcs. Main Propulsion Propeller Blades suffering from cavitation locally, same location addressed on all 8 blades.

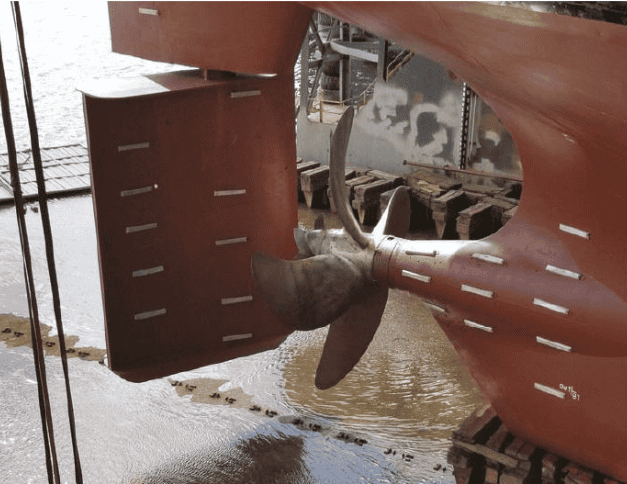

Protection of Propeller Shaft

A propeller shaft was exposed to severe bi-metallic corrosion, but protected again with layers of Wencon Coating white and blue.

Rebuild of Thruster Bow Casing

The corrosion was so severe that visible pitting had formed, requiring a complete rebuild.

Ship repair and maintenance

- Ballast valve casings

- Bearing Seat fixation

- Cast to fit of rudder pin bearing house

- Casting Rudder trunk bushing

- Casting rudder pintle & blade seat

- Cooler End cover

- Corroded Stern Tube

- Cylinder Liner

- Diverter Head

- Dredging Sand pump

- End cover for industrial condenser

- End covers for coolers

- Engine wet Liners

- Exhaust Gas Boiler tubes

- Gear shaft

- Heat Exchange cover

- Heating Coils manifold

- Hydraulic Rams

- Impeller

- Leak from HFO tank to reefer cargo hold

- Mud Pump wear

- Multitubular Condenser

- Propeller Nozzle

- Propeller shaft

- Propeller Shaft repair

- Propeller Blades Cavitation damage

- Rebuilding of Stern Boss flange

- Reinforcement of pipes and welding seams

- Refurbishment of Thruster housing

- Rudder Refurbishment and Protection

- Rudderstock rebuild and protection

- Rudder Link & Hinge System Refurbished

- Scrubber Outlet Protection

- Screw Pump

- Seawater Filter

- Single Case Pump

- Split case pump

- Split case firefighting Pump

- Split casing Pump refurbished & protected

- Suction Wells

- Support Bearings/ Hydraulic Drive for Jack Up

- Thruster tunnel

- Thruster Tunnel protection

- Turbo Charger Housing

- Thruster gear Housing

- Water Jet tunnel

- Water Jet intake

- Water jet casing