Rebuild of Bow Thruster Casing

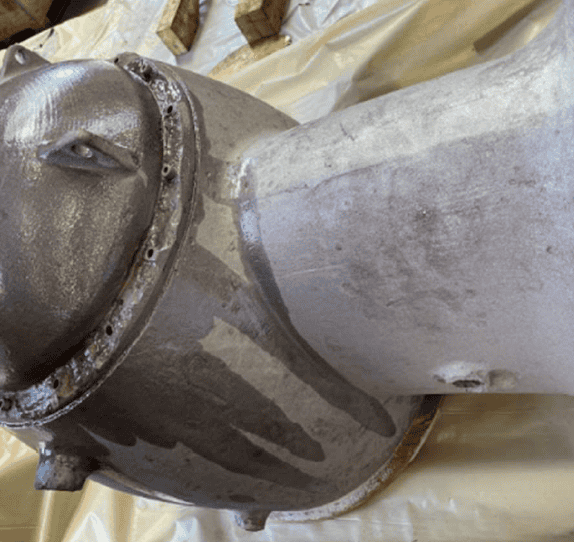

Refurbishment of Bow Thruster Casing that was heavily corroded with visible pittings.

A heavily damaged casing

A bow thruster casing is a protective housing for the bow thruster, a critical system that aids in maneuvering the ship, especially in tight spaces like harbors.

Over time, the casing can suffer from corrosion due to constant exposure to seawater. In this case, the corrosion was so severe that visible pitting had formed, requiring a complete rebuild.

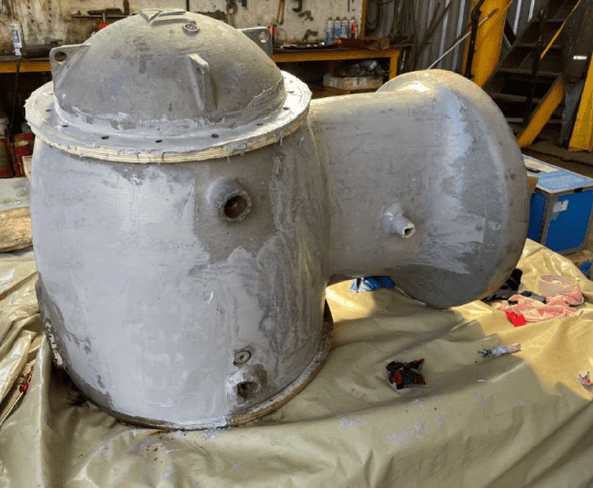

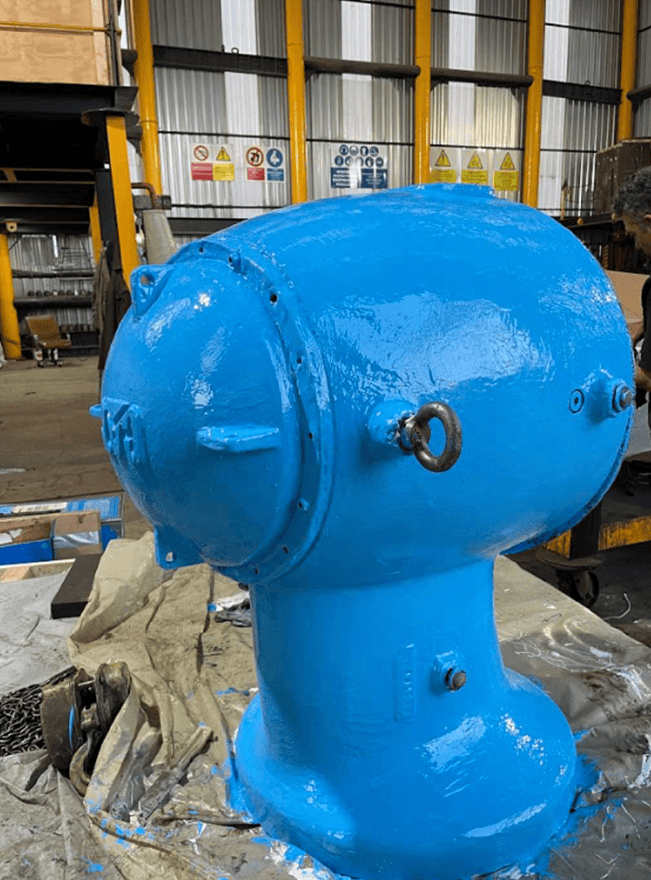

Using Wencon epoxy solutions, the casing was restored and protected against future corrosion, ensuring long-term durability and efficiency.

Rebuilt to original shape by using Wencon

The Wencon materials used at this job

can be machined, drilled and worked like metal, after curing. Note the contact surface, which was heavily damaged; is now rebuild to original shape. The steel is now separated from the seawater, and will not be attacked

by bimetallic corrosion for many years.