Wencon Epoxy Solutions Protecting Maritime Equipment

At Wencon we prefer repair over replace.

Our mission is to protect your equipment against corrosion with repair and maintanence epoxy solutions in order for you to reduce cost and downtime. Keep operating with Wencon solutions against corrosion and expand the lifetime of your equipment with temporary and permanent epoxy repairs.

Explore common repair solutions

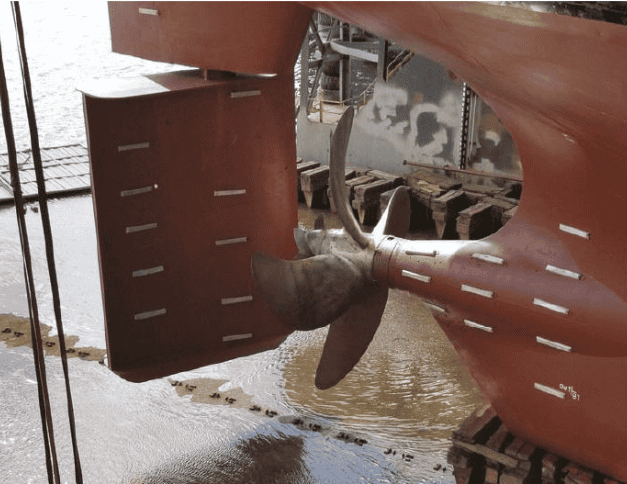

Rudder Repairs

Maintain the integrity and performance of your ship’s rudder with our Wencon solutions. Rudder blades are prone to cavitation and corrosion, especially in aggressive marine environments. The construction involves welded plates that can suffer from wear and rust, particularly at the weld seams. Our repairs include filling these seams with high-quality materials, reinforcing the structure effectively.

We also address issues such as loose bearings and bimetallic corrosion, which can cause significant damage over time. Our services include casting new thrust and bearing bushings, ensuring a precise fit and restoring the rudder’s functionality.

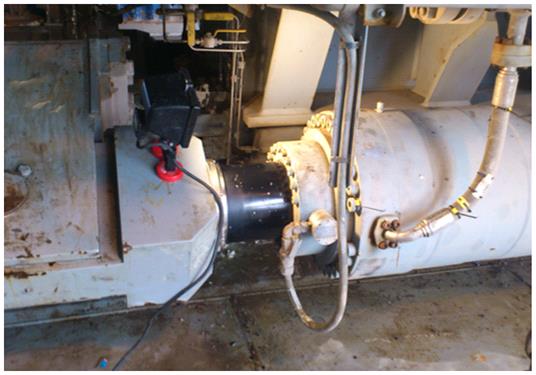

Stern Tube

Ensure the reliability of your ship’s propulsion system with our guidance to repair and protect the stern tube. The stern tube, where the propeller shaft exits the hull, is highly susceptible to bimetallic corrosion, which is often left unpainted and can sneak into the main propeller or stern tube seal boxes. This corrosion can lead to leaks and misalignment in the seal boxes, posing serious operational risks.

Our repair solutions address these issues efficiently, often completing the necessary repairs within a day, minimizing both cost and downtime. Protect your vessel from costly damage and operational delays with our expert stern tube repair services.

Propeller Cavitation

Protect your propeller blades from the damaging effects of cavitation with our specialized repair services. Cavitation, caused by vacuum on the pressure and suction sides of the blades, can lead to significant erosion, much like sandblasting a single spot repeatedly. This damage is commonly seen on rudders and propeller blades.

Our repair solutions involve filling and reinforcing these damaged areas with new material, effectively preventing further cavitation damage. By detecting and addressing cavitation early, we can ensure that your vessel continues to operate smoothly and efficiently, using Wencon products to provide a lasting solution.

Exhaust Repair

Keep your ship’s exhaust systems operating smoothly with our repair solutions for exhaust systems made for high temperature. Exhaust components, including bellows and compensators, are prone to damage from engine vibrations, high temperatures, and sulfur in exhaust gases.

These conditions can lead to cracks in expansion joints and weld failures. Our repair services tackle these challenges head-on, ensuring your exhaust systems withstand the challenges of fuel combustion.

Heat Exchange Covers and Coolers

Enhance the efficiency and longevity of your ship’s heat exchange systems with our specialized repair services. Heat exchange covers, also known as end covers, and plate heat exchangers can suffer from rust and expansion, leading to internal pressure and leaks. Our expert repairs ensure these end plates are fully rebuilt and perfectly flat, preventing future issues.

We also offer comprehensive services for pipe coolers, including the restoration of pipes, end covers, and return covers, significantly extending their lifespan. Trust Wencon solutions to keep your cooling systems in top condition.

Seawater Filter

Protect your ship’s seawater intake systems with our repair solutions for filters, strainers, and housings. These components are constantly exposed to both corrosion and bimetallic corrosion, affecting all types of water entering the vessel, including:

- process water

- cooling water

Corrosion can lead to leaks, allowing water to enter the ship, which is something you of course want to avoid.

Our Wencon repair solutions ensure your seawater strainers and housings remain intact and efficient, preventing unwanted water ingress and maintaining the integrity of your vessel.

Scrubber Outlet

Ensure the integrity of your scrubber outlets and the surrounding hull with our repair services. Scrubber wash water flows through GRE pipes and stainless steel valves that resist corrosion, but as it exits through the overboard pipes, it can often cause significant damage to the surrounding hull. This common issue is frequently overlooked during routine maintenance.

Our repair solutions address the degradation caused by scrubber wash water, reinforcing overboard pipes and protecting the hull from corrosive damage.

Explore how our comprehensive repair services can prevent and resolve issues with your scrubber outlets, ensuring the longevity and safety of your vessel.

Handle scrubber challenges with ease

Scrubber outlets, hulls, and water systems face harsh conditions, leading to corrosion and wear. The acidic, corrosive wash water from scrubbers, combined with high exhaust gas temperatures, can severely impact your vessel’s structural integrity.

We have created a whole page just for the solutions we provide for scrubber areas.

Case: Repair of Scrubber Unit

Time management is crucial during such repair jobs, to avoid or eliminate downtime completely. The mobile team from Gardit were able to complete the repairs on both scrubber unit in 13 hours, and the scrubber was running again after curing for 12 hrs 20º

Read the full case by clicking on the link below.

Pumps

Ensure the reliability and efficiency of your ship’s pumps with our repair services. Pumps are critical components on any vessel, and common issues like bimetallic corrosion can cause significant problems, even in pumps less than a year old. Our solutions are designed to address these issues effectively, particularly in firefighting pumps and other essential systems. We offer comprehensive repair and rebuilding services to fix damage and provide permanent solutions, all with tools and materials readily available on board.

We have provided several solutions for different pumps, as:

- firefighting pumps

- split case pumps

- single case pumps

- screw pumps

Heating Coils

Combat external corrosion on heating coils manifolds with our proven solutions. Our task is to provide a viable and lasting solution to this persistent problem. We offer a solution that enables your crew to perform repairs using accessible tools typically found on board a tanker, without the need for special equipment. Ensure the longevity and efficiency of your heating coils with our reliable and easy-to-implement epoxy repair methods.

Discover how our innovative solutions can protect your heating coils manifolds from corrosion and enhance your vessel’s performance.

Hydraulic Rams

Optimize your vessel’s operations with our specialized repair services for hydraulic rams. Rebuilding the surface of hydraulic pistons, especially those with chrome and ceramic coatings, can prevent costly replacements. These pistons are expensive, and repairing them can result in significant savings for shipowners. Taking a ship out of charter for piston replacement is extremely costly. Our epoxy repair solutions allow you to refurbish cylinders within a few days, avoiding the hassle and expense of cutting out and installing new cylinders.

Discover how our efficient repair services can keep your hydraulic rams in top condition and save you time and money.

Temporary Pipe Reperation

Avoid downtime and ensure your ship’s safety with our temporary leak repair solutions, including GRE and all types of steel. Whether you need a quick fix for leaks or a longer-term solution, our temporary repairs can stop leaks effectively. GRE pipes can also become permanent solutions with the proper class approval. The repair solutions can function as temporary class approval until the next docking, ensuring compliance and safety. Suitable for all types of pipes and general piping needs.

Thruster Gear Housing and Tunnels

Thruster gear housings often suffer from bimetallic corrosion due to the presence of multiple metals in a confined space, placing high demands on zinc anodes. Instead of allowing corrosion to damage the unit, a stainless steel ring is welded inside the thruster. The cast iron thruster is more susceptible to corrosion compared to the ship’s hull and the stainless steel ring. Propellers on the thruster resist corrosion better, but the welded joint between the stainless steel ring and the thruster can still lead to significant bimetallic corrosion, causing the ring to loosen. This area can be protected effectively.

With numerous mechanical parts that need to fit together perfectly, replacing a thruster often involves a long wait time, leading to significant cost savings when opting for effective protection solutions by Wencon.

Anchor & Mooring Winch

Refurbishment and general corrosion protection in the area of achor and mooring winch, for instance:

- Refurbishment of holding break

- Cast to fit bearings, liners and bushings

With Wencon products, we are able to build up the construction to original shape and apply a double layer coating which will protect the asset against future corrosion.

Tank Pittings

Protect your ship from the damaging effects of tank pittings caused by corrosion and wear in the suction well due to high flow rates.

Over time, paint can erode, leading to wear on the steel and other materials. Our solutions effectively stop pittings by sealing them, preventing holes that could compromise the integrity of your vessel. Avoid costly repairs and maintain your ship’s safety with our specialized sealing techniques.

Ballast Pipes

Ballast water is essential for maintaining safe operating conditions throughout a voyage. It reduces stress on the hull, enhances transverse stability, improves propulsion and maneuverability, and compensates for weight changes due to varying cargo loads and fuel and water consumption. However, when ballast pipes start leaking, it can compromise these benefits and pose significant operational challenges.

Avoid downtime and stay operating

From repair kits onboard to on-site maintenance, our wide range of epoxy repair and maintenance solutions reduce your vessel’s downtime, cost expenses and carbon footprint in scope 3.

All by choosing repair over replace.

Get CO2

calculations

The shipping industry handles 90% of global trade and transports over 11 billion metric tons of goods annually. However, it accounts for 2% to 3% of global greenhouse gas emissions. In 2023, the International Maritime Organization set a goal of achieving net zero emissions by around 2050. Source: BCG.com

We have partnered with Reflow to provide CO2 calculations in Scope 3, demonstrating the benefits of repairing rather than replacing equipment.

And that’s useful data for the maritime industries’ green accounting.

Make your time count with our new sprayable coating

Wencon UW Coating LV for Spray Application is maritime epoxy repair and maintenance redefined.

With its low viscosity, the two component epoxy is mixed directly in the application process through the catridge gun. Therefore, you are able to reach larger areas faster and more effeciently.

Explore our products

Wencon Coating

Wencon Coating is a two-component, liquid epoxy coating suitable for a wide range of applications. It provides a smooth non porous

Wencon UW Coating

Wencon UW (underwater) Coating is a two-component product, to be applied on wet surfaces or underwater.

Epoxy products for rebuilding and protection

Our materials are designed to provide protection of surfaces, exposed to galvanic corrosion, cavitation, wear or breakage

On-board temporary repairs

Avoid downtime with a Wencon repair kit on board your vessel for emergency and temporary repairs.

On-site repair and maintenance

Minimize costs on your budget and extend the life of your parts by using Wencon epoxy solutions for your repair jobs on-site.

Solutions by workshop or shipyard

We can assist you in locating a Wencon certified Workshop or Shipyard, or you can use your prefered partner.

Subscribe to our newsletter

Get monthly e-mails with updates on our latest solutions, products and success stories.