Wencon Scrubber Solutions

Wencon epoxy solutions improves the efficiency of your scrubber systems, reduce downtime, and extend their lifespan.

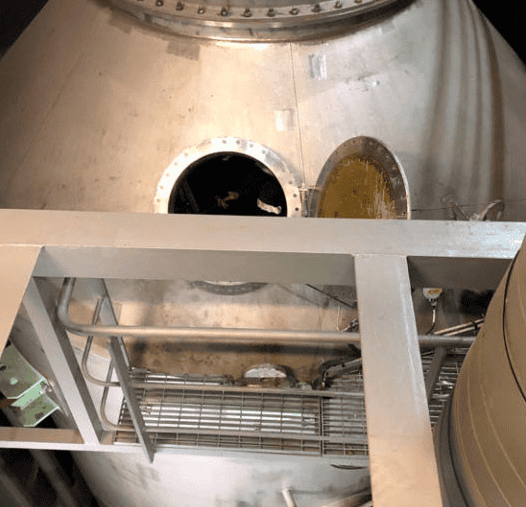

Scrubber outlets, hulls, and water systems face harsh conditions, leading to corrosion and wear. The acidic, corrosive wash water from scrubbers, combined with high exhaust gas temperatures, can severely impact your vessel’s structural integrity.

Handle scrubber challenges with ease

With the IMO 2020 Global Sulphur cap regulations, shipowners worldwide are focused on preparing their vessels to comply.

Scrubbers present a new challenge, handling highly corrosive wash water throughout the vessel. The most vulnerable areas are where metal contacts the wash water.

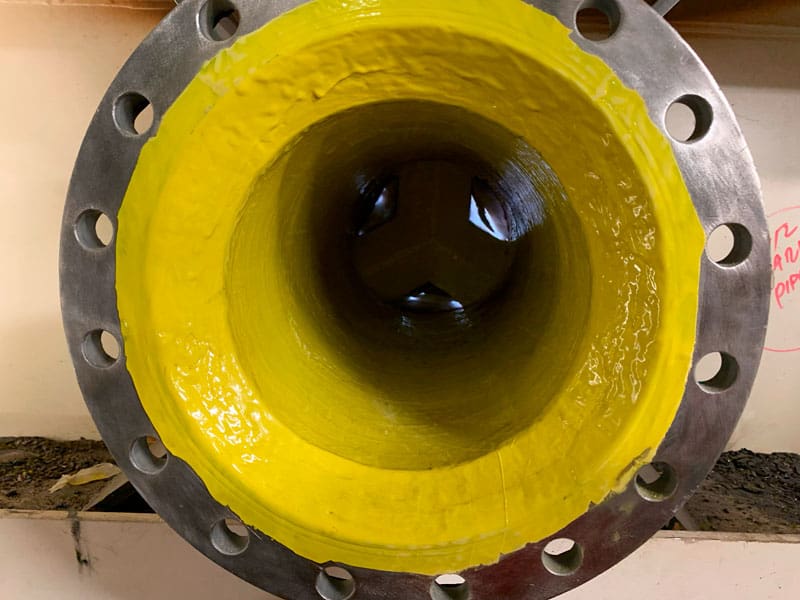

Wencon Hi-Temp coating, a solvent-free epoxy coating, provides robust protection against sulfuric acid and low pH levels in the wash water, ensuring the longevity and integrity of your vessel.

Repair of GRE scrubber pipes

We have successfully supplied several hundred vessels with a specific GRE & Steel pipe repair kit, using our well-proven method of wrapping the section of damaged pipe with interchanging layers of fiber reinforcement tape and Wencon UW Coating.

The Wencon UW Coating makes it possible to start the application of the coating to the pipes when the area is still wet. This allows for the vessel to be back in operation 8-10 hours after the application has been completed.

Let’s have a talk about Wencon scrubber solutions

Interested in learning more about how Wencon’s epoxy solutions can protect your scrubber systems?

Reach out to our Area Sales Manager, Bo Pedersen, for personalized assistance and detailed information.