Repair of Corroded Heat Exchange Cover

Corroded heat exchange cover

Bi-metallic corrosion often leads to leaking covers on heat exchangers, a well-known issue in the industry. The delivery time for a new cover is typically quite long. However, with Wencon repair solutions, the cover can be refurbished and back in action within 2 days.

In this specific case, severe corrosion around the sealing points caused the heat exchanger to leak, presenting a significant challenge.

Heat exhange cover restored

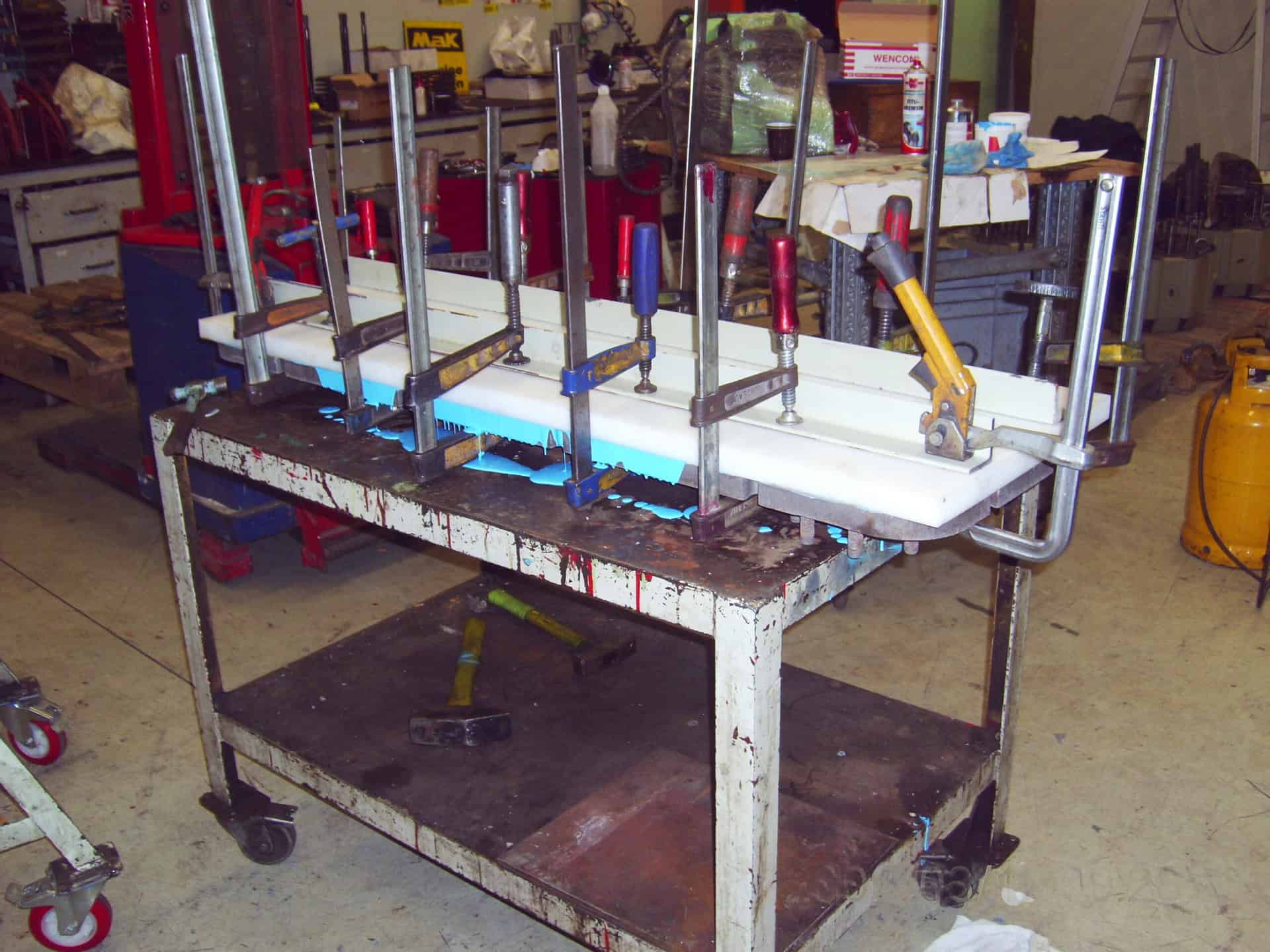

The severely corroded cover required thorough preparation to ensure optimal conditions for the application of Wencon material. The end cover was first blasted and heated to remove any moisture. Wencon Rapid repair material was then carefully applied to the cover.

Finally, to fill and smooth small pitting holes, a thin layer of Wencon Blue coating was applied to the plate and similarly put under pressure. The end cover was then reinstalled, and the heat exchanger was reassembled and back in action.