Repair of Cavitated Main Propulsion Propeller Blades

Cavitation? No problem. Wencon Ceramic Cream combats cavitation damage on main propulsion propeller blades and postpone damage and extend the lifetime.

Eight main propulsion propeller blades cavitated

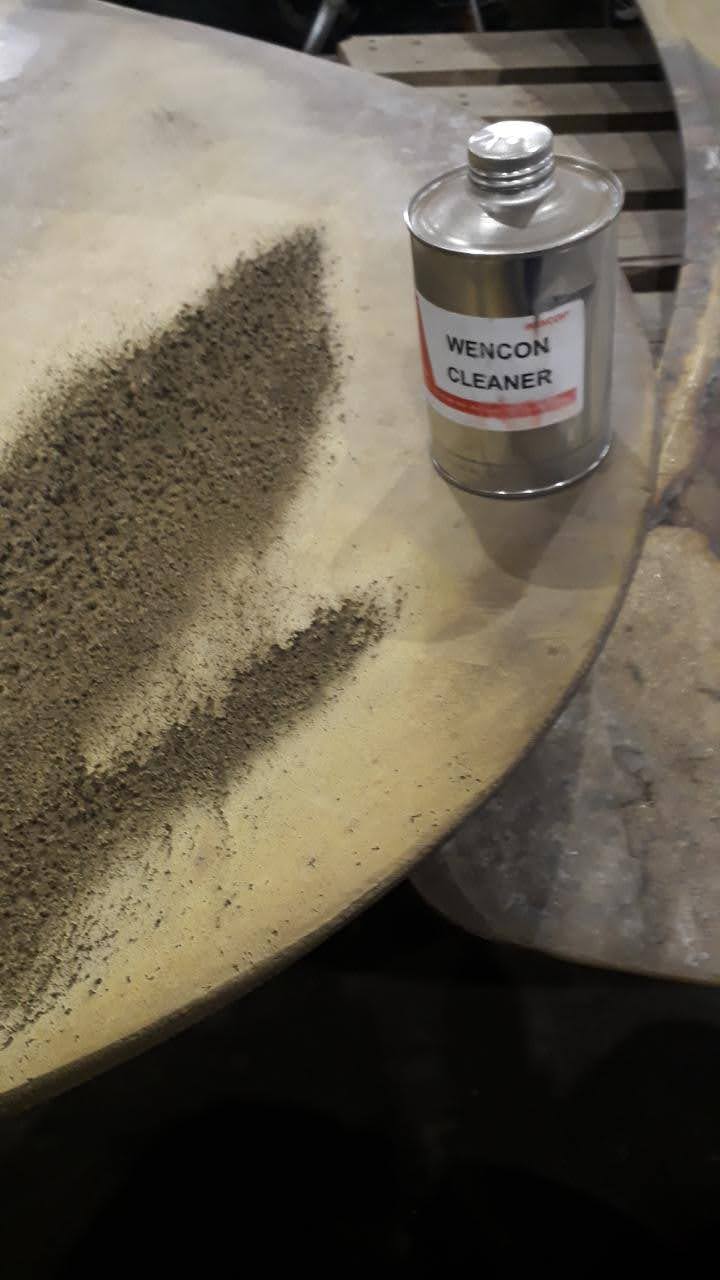

Eight main propulsion propeller blades have been suffering from cavitation damage with the same issue affecting all blades. Cavitation, one of the most damaging phenomena for metals, occurs due to rapid pressure changes in liquids, creating vapor bubbles that implode and generate intense shock waves.

This relentless impact is akin to continuous shot blasting, which no steel or coating can permanently withstand. The challenge is to find a solution that protects these blades from such severe and ongoing damage.

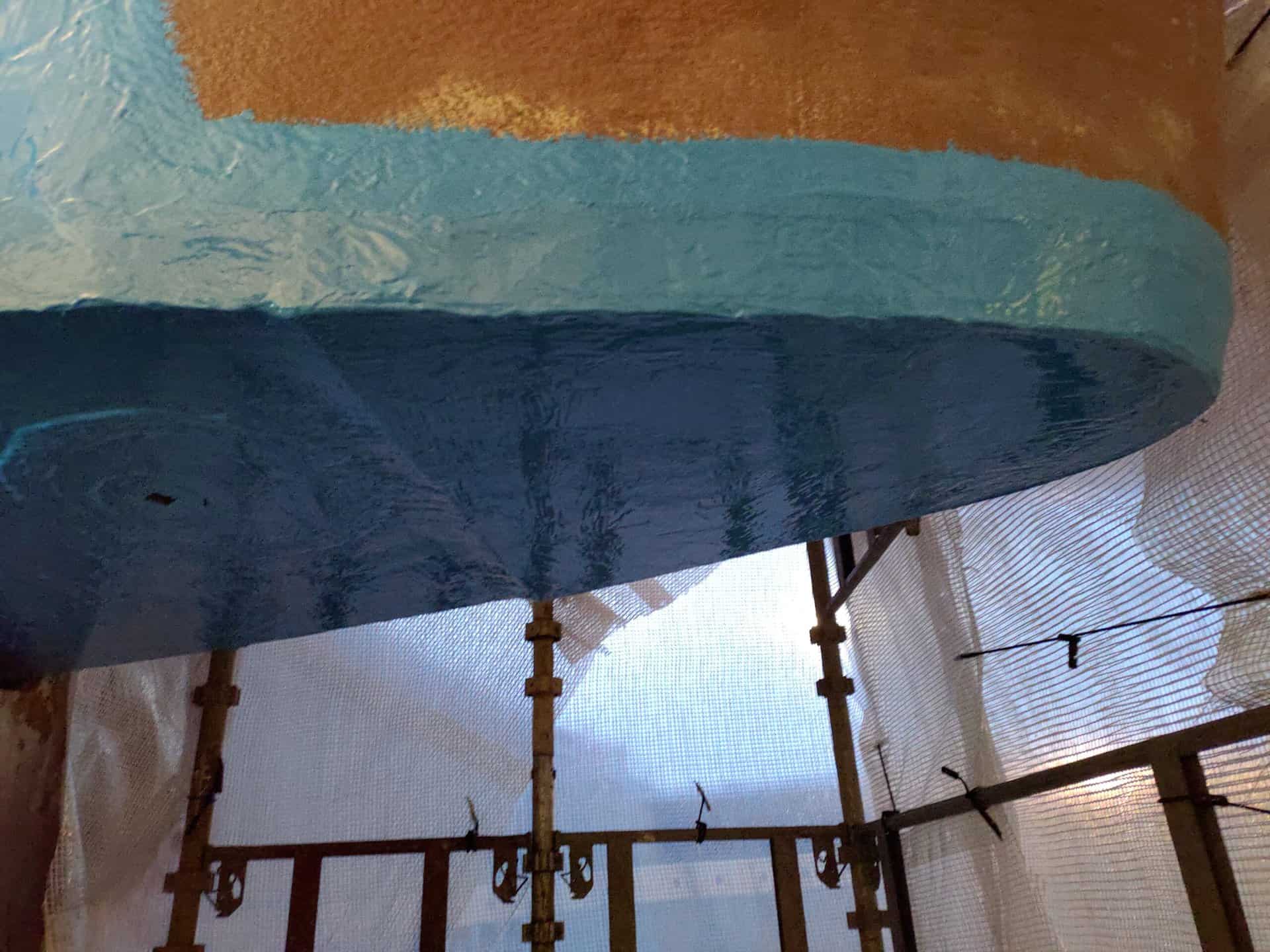

Postponed cavitation attack on the metal after coating

To combat the cavitation damage on the main propulsion propeller blades, Wencon Ceramic Cream was applied. This coating significantly postpones the cavitation attack on the metal, preserving the physical properties of the blades by allowing the ceramic layers to absorb the damage.

While the exact longevity of the Wencon application against cavitation is uncertain, it effectively delays further damage and is an essential part of the maintenance program. By providing a durable barrier, Wencon Ceramic Cream protects the propeller blades from continuous cavitation impacts, ensuring prolonged service life and reliability.