News

1. november 2024

Efficient Dry Docking with Wencon solutions

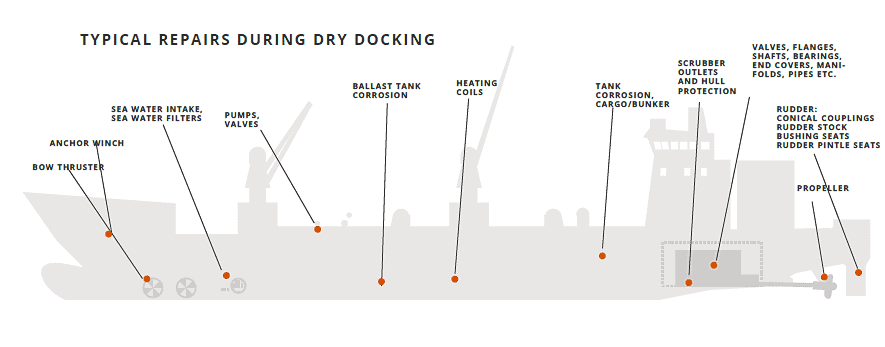

With Wencon we offer a wide range of dry docking solutions so you can prepare for those problems that are most frequently during planned docking.

Thorough Planning Ensures Successful Dry Docking

Months of preparation go into each dry docking—a complex and costly process. This requires careful inspection of all parts of the vessel to ensure that maintenance and repairs are meticulously planned.

However, limited access to certain areas of the vessel before docking means some parts cannot be inspected in advance, introducing uncertainties into the dry docking plan. That’s why we encourage thorough planning to minimize risks and ensure a smoother dry docking process.

By prioritizing repair over replacement, you can save valuable man-hours, reduce unnecessary downtime, and get your vessel back in service quickly and efficiently. With more than 1000 possible repairs all Wencon products are Type Approved by 4 major classifications.

Repair, Replace & Reflow

With more than 1000 possible repairs all Wencon products are Type Approved by 4 major classifications. Typical repairs contains both internal and external solutions

External repair case: Rebuilding of Thruster Gear Houseing

A severe corrosion issue in the vessel’s thruster gear housing threatened the system’s operation and efficiency, risking costly downtime and financial loss if left unaddressed.

The refurbishment successfully restored the thruster gear housing to its original condition with enhanced corrosion protection. Wencon Coating effectively shielded the steel from seawater, reducing bimetallic corrosion risks for years. This cost-effective solution provided significant savings and minimized downtime compared to replacing the unit

Internal repair case: Coating a Seawater filter

A new seawater filter generally comes with a thin, epoxy paint coating that lacks strong resistance to seawater. By applying Wencon’s metal-free epoxy systems, we prevent bi-metallic corrosion and greatly extend the service life of essential and costly equipment on board the vessel.

The process began with preparing the filter for shot blasting, achieving a rough surface to ensure the Wencon Coating would adhere well. After blasting, the housing was cleaned with Wencon Cleaner to remove contaminants. The Wencon 2-layer system was then applied in two 300-micron layers (White and Blue) for a total thickness of 600 microns, with the second layer applied while the first was still tacky to ensure bonding. Once the coating cured, the stainless steel filter insert was installed, and the exterior received a final paint finish.

Interested in our dry docking solutions? Feel free to contact us!

A Customized Repair Kit For Dry Docking

By having a Docking Kit on board before docking, you can list it in the Docking Specification as “owner-supplied.” This helps you avoid delays and extra costs from unexpected repairs during dock inspections. Wencon’s Customized Repair Kit is designed to handle corrosion and wear efficiently, ensuring your vessel is back in service quickly and reliably..