Rebuilding of Cylinder Rams

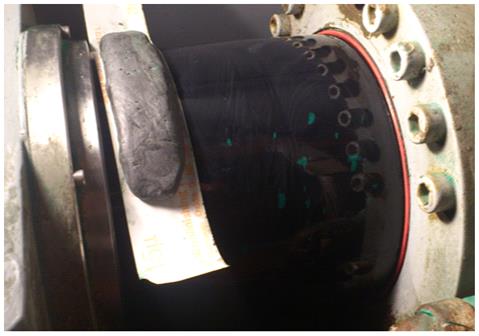

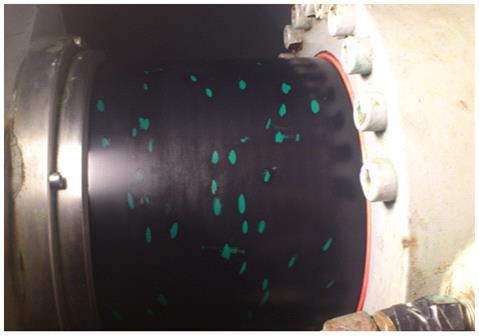

Bubbles under

original ceramic coating will

cause oil leaks from seals

A hydraulic ram presented a significant challenge due to visible bubbles under its original ceramic coating. These bubbles indicated imminent failure, as they were likely to burst and cause oil leaks from the seals. One of the bubbles had already cracked, revealing a damage area of 50 x 80 mm and 2-3 mm deep. This posed a risk of severe operational issues if not addressed promptly.

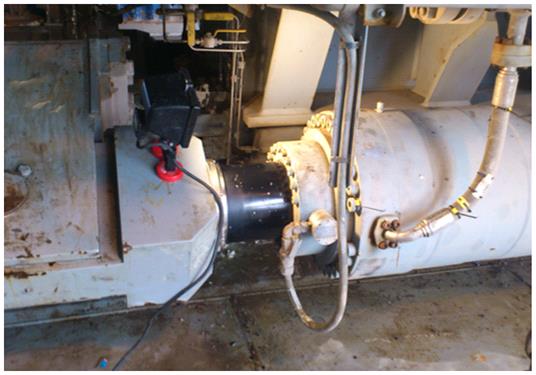

Hydraulic ram restored

To repair, all areas to be treated were masked with tape to avoid material waste. Wencon Hi Temp was applied using a brush and spatula until the original surface level was restored. The application process was repeated as necessary, and the material was allowed to cure for 10-12 hours at a minimum temperature of 15°C.

A grinding tool was then created using Wencon putty, allowing the surface to be hand-sanded to nearly its original shape and size. The final result was an intact surface, restored to its original condition and ready for many more years of service.