Protection of Propeller Shaft

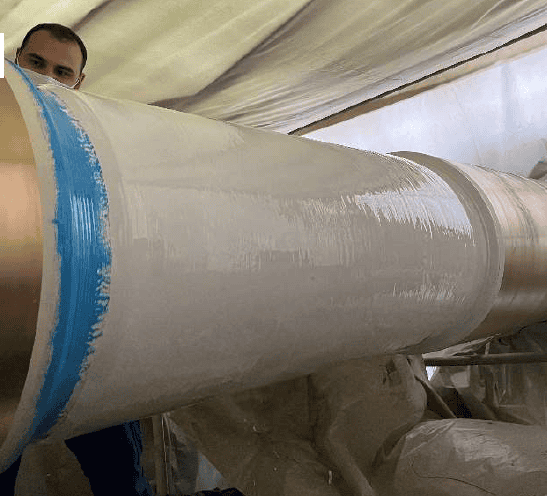

This propeller shaft was exposed to severe bi-metallic corrosion. By applying Wencon epoxy products, you are able to protect your ship equipment against future corrosion and avoid replacing it for newer parts. It is cost friendly and good for the green maritime agenda.

A common problem among propeller shafts

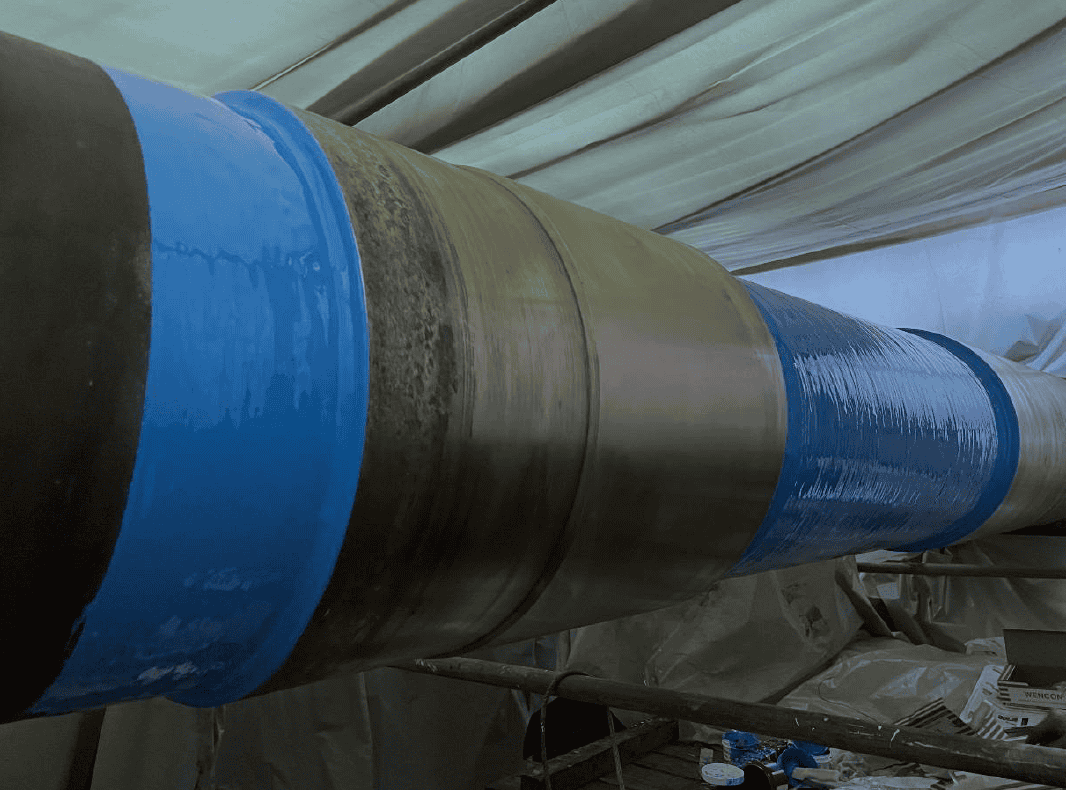

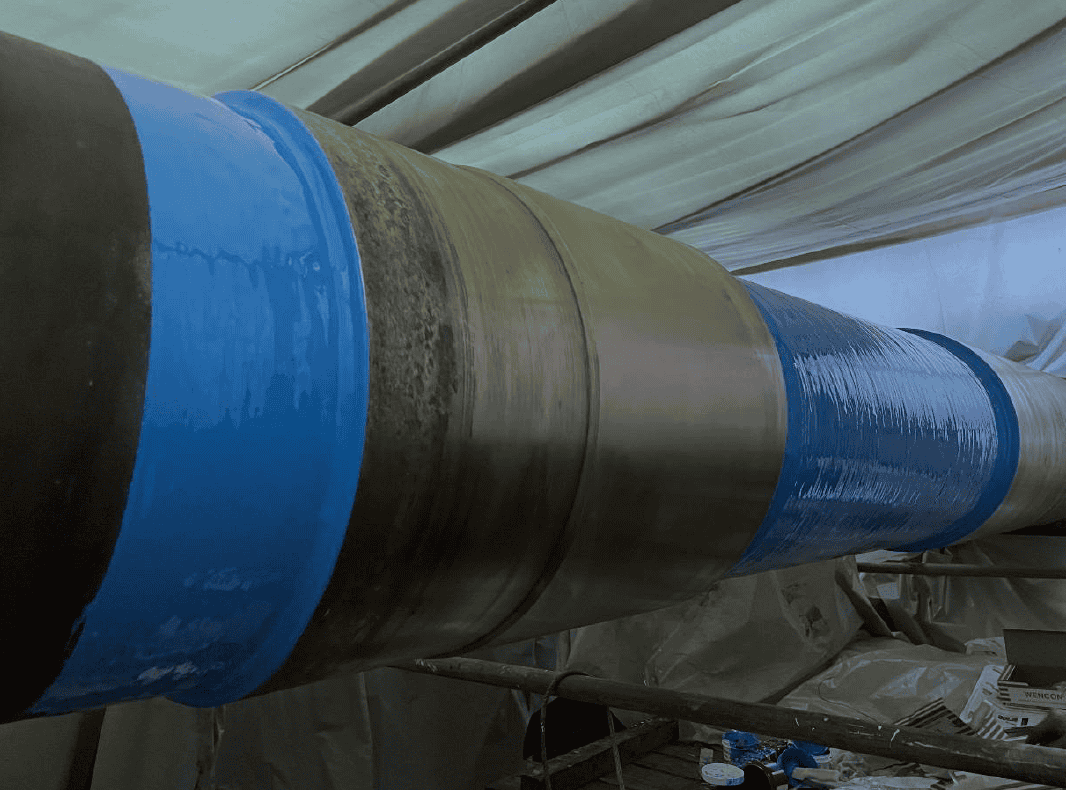

Bi-metallic corrosion, also known as galvanic corrosion, occurs when two different metals are in electrical contact with each other in the presence of an electrolyte, such as seawater. This reaction often leads to accelerated corrosion of the less noble metal, resulting in significant damage to propeller shafts over time. This type of corrosion is particularly concerning in the marine environment, where the combination of saltwater, varying temperatures, and constant exposure to harsh elements makes propeller shafts vulnerable. Therefore, it was crucial to act upon the damage and rebuild and protect the propeller shaft against future corrosion.

Propeller shaft can now withstand future challenges

After applying Wencon White and Blue coatings to the propeller shaft, the shaft is now shielded from future corrosion. This robust, dual-layer epoxy provides a resilient barrier against the harsh marine environment, ensuring the propeller shaft’s lifespan and reducing the need for frequent maintenance. With Wencon’s protective epoxy coating, the propeller shaft is well-equipped to withstand the challenges of bi-metallic corrosion, ensuring reliable performance for years to come.