Coating of a Seawater Filter

A new sea water filter typically comes with a thin epoxy paint-based coating, which lacks strong resistance against sea water. By using Wencon’s metal-free epoxy systems, we eliminated bi-metallic corrosion and significantly extended the service life of critical and costly equipment on board the vessel.

Bi-Metallic Corrosion

A new sea water filter typically comes with a thin epoxy paint-based coating, which lacks strong resistance against sea water.

Additionally, the stainless steel filter insert induces bi-metallic corrosion. This occurs because the presence of two different metals causes the steel filter housing, with the lower potential, to corrode and eventually leak.

Sea water filter housings are often made from cast iron or cast steel, with cast iron being the lower quality option. In this particular case, the new filter housing was constructed from steel plate and included a stainless steel insert.

The Process

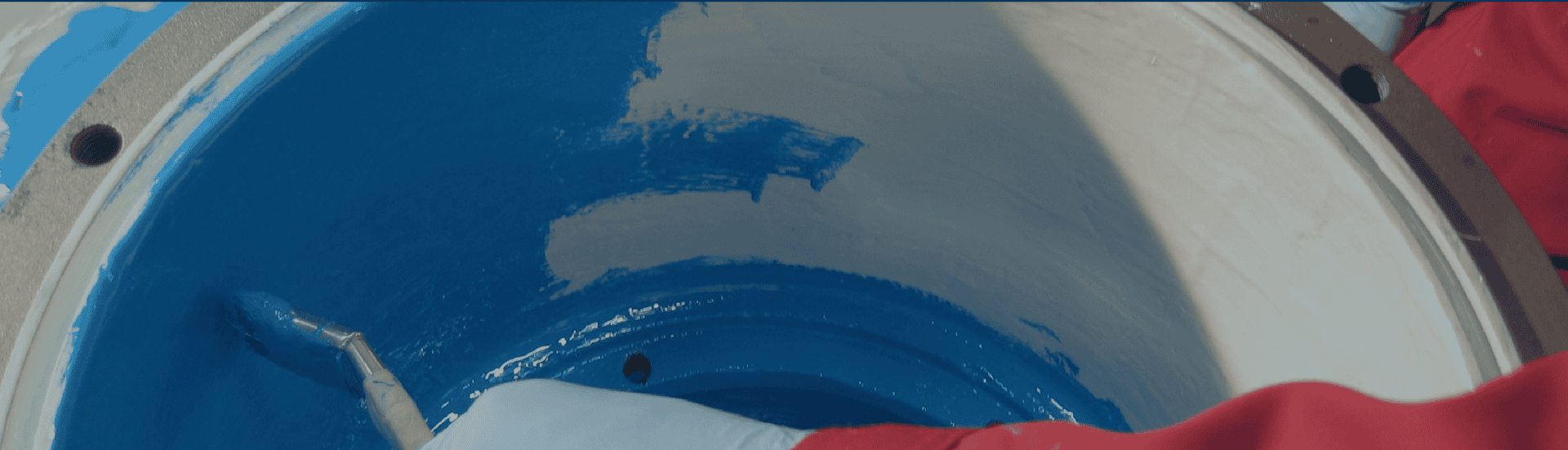

The first step involved preparing the filter for shot blasting. The filter was shot blasted to SA 2.5, achieving a roughness of 70-75 microns, which ensures optimal adhesion for the Wencon Coating.

After shot blasting, the housing was thoroughly cleaned using Wencon Cleaner to remove any contaminants.

Next, the Wencon 2-layer system was applied. Coating White and Blue were each applied at 300 microns, resulting in a total thickness of 600 microns. The second layer was applied while the first layer was semi-cured and still tacky to ensure proper bonding.

Once the coating was fully cured, the stainless steel filter insert was installed, and the exterior received a final paint finish.

Future Corrosion Protection

The filter unit is now protected for at least 10 years, provided the crew handles the insert carefully during installation to avoid impact damage to the coating.

To ensure ongoing protection, the crew was supplied with Wencon Coating for on-board repairs of any potential impact damages. Regular damage inspection is crucial and applies to all coating systems, regardless of brand.

By using Wencon’s metal-free epoxy systems, we eliminate bi-metallic corrosion and significantly extend the service life of critical and costly equipment on board vessels.